‘Egg-citing’ venture — Enve Ag LLC opens chicken farming operation north of Greenwood

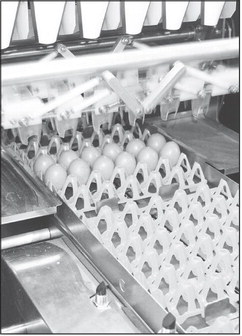

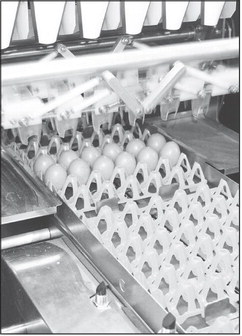

On Sept. 10, Enve Ag LLC held an open house at its new poultry barn located at the Kenneth Martin farm at N10637 Madison Avenue in Greenwood. The new barn houses the first VDL Jansen aviary system ...