Fair Cut Meats in Unity makes customer service a priority

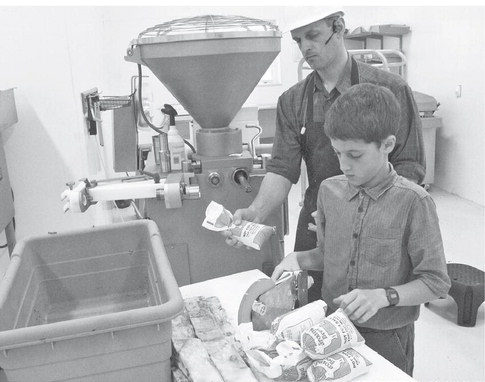

On a recent weekday afternoon in Unity, Merlin Beachy and his oldest son, Arthur, worked side by side to turn out a fresh batch of ground beef at their business just south of Unity. The father-son duo did their work in a small, white room, surrounded by stainless steel and fresh cuts of bright-red meat.

Over the last year and a half, Fair Cut Meats, N11187 Fairhaven Ave., Unity, has quietly established itself as the newest custom meat processor in Central Wisconsin’s thriving community of small-scale butcher shops.

“Because we do custom work, we’re catering to the people who want to know where their meat comes from,” Beachy said.

The fact that Fair Cut Meats relies on simple, timehonored methods rather than sending its products through an assembly line “is probably our biggest selling point,” he said.

Beachy, who grew up on a farm and worked as a dairy farmer for 10 years, first learned to butcher under the tutelage of Luis Martin, owner of Martin’s Meat Processing in Withee, before striking out his own with his family, which includes his wife, Delores, six children and one on the way. Beachy said he still calls Martin on occasion to ask him for advice.

“This is kind of a new venture for us,” he said. “We did some of our butchering, but I worked for someone else for a few months and then we started here.”

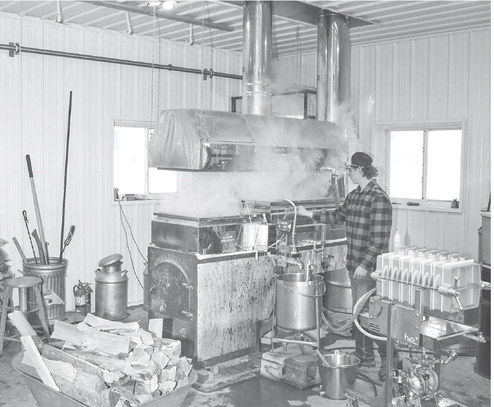

Once he decided to establish his own business, Beachy said it took him the better of a year to build his 4,000square-foot facility and get it up and running by January of 2024.

In between dairy farming and meat processing, Beachy and his family lived in the Dominican Republic for three years on a mission trip for their church. They got to know quite a few people while working with the congregation there.

“It’s a place we’d like to go visit again,” he said. “We enjoyed it there.”

Now back in Wisconsin, Beachy and his family spend their days making quality products for customers who appreciate custom butchering.

“A lot of our work is simply cutting up meat – steaks, roasts and ground meat – but then we also do seasoning, especially with sausage,” he said. “We do brats and seasoned sausage in one-pound bags.”

Fair Cut Meats also smokes hams, bacon and snack sticks. They’ve had a good response so far to the pigs they’ve processed, Beachy said.

“Word’s getting around,” he said. “People say ‘So-andso told me that you do hams and bacon, and they’ve turned out real good.’” Most of the products made by Fair Cut Meats come from animals brought in by the customers, but Beachy said they can also find pork and beef from outside sources. As a custom butcher, Fair Cut Meats returns all of its customers’ meat directly back to them.

“We do not sell meat here,” he said. “We’re not licensed for that.”

Wisconsin’s deer hunting tradition also feeds into the Fair Cut Meats business model.

“Venison is another thing we do,” he added. “More in season than out of season, but people bring it in throughout the year and me make summer sausage.”

Beachy said they like to get their customers’ deer skinned out within a week or so, but if they’re not frozen, they want to do it within a day or two. The deer will hang in their cooler for a week or more before they’re deboned, bagged and stored in a freezer.

“Once we’ve done that, we’ll kind of go back to pork and beef,” he said. “As we get windows of time, we work on the different products.”

Beachy said he told his customers last year to expect about a month before their venison was ready, but if they were to get busier, that turnaround time could stretch out a little longer. He said they have a 20-pound limit on the size of batches they produce.

When it comes to beef, Beachy likes to add some extra time in the process to improve the quality of what his customers get back.

“That’s something maybe not a lot of butchers do, but we let it hang for two weeks,” he said. “It ages the meat and makes for tender roasts and steaks. It’s the enzymes at work. It’s a controlled aging process that makes the meat much more tender.”

To flavor his products, Beachy orders spice mixes and makes a few of his own. He said they make his brats taste better than anything you can buy at a convenience store.

Beachy said Fair Cut Meats focuses on cleanliness, affordability and strong customer service, which draws in meat-lovers from as far away as Merrill.

“We want to take care of our customers,” he said. “I suppose everyone does, but if there’s a problem, we want to make it right.”

Looking ahead, Beachy said his son Arthur is getting to know how to use the butcher’s knife, which will “make a big difference on the cutting table.”

“That’s probably one of the biggest things that pushed us into starting this: it’s a family operation,” he said. “We can work with the children together.”

Fair Cut Meats can be reached by calling 715-613-2781. The shop is open from 8 a.m. to 5 p.m., Monday through Friday.