Sweet enterprise Sugar Moon Hills looks forward to start of season with new sugar shack

In Native American folklore, the sugar moon is the last full moon before spring and typically occurs just before the sap of sugar maples begins to flow.

For local maple syrup producers Gene and his sons Chris and Jon Knoll, the name was an appropriate one as they began work building a new sugar shack and expanding their sap operations.

For the past year, the family has been hard at work making Sugar Moon Hills a reality with the installation of a new sugar shack on the family property located on Sunset Road in the town of Medford.

In planning for the sugar shack, Jon Knoll explains that they did their homework learning what works and doesn’t work as well for other producers and what they needed their operation to do.

The Knolls are no strangers to maple syrup production. They have collected sap for many years working with other producers as suppliers. Through it all, Jon said they had the goal of starting their own business, one that not only included wholesale syrup but included retail opportunities, education and agricultural tourism. In its simplest, maple syrup is produced by concentrating the sap from the sugar maples (Acer saccharum) from the 2 to 5% concentration found in nature to around 66% in the finished syrup. The process of cooking down the syrup has changed with technology over the years going from open pans over a wood stove to evaporators and in recent years the use of reverse osmosis.

In planning for their operation, the Knolls chose to invest in a larger reverse osmosis (RO) system and start with a fuel-oil powered evaporator able to produce about a barrel of syrup per hour. Planning for the future, the evaporator room was designed to allow for the easy addition of a second larger evaporator with fuel lines and pipes built into the concrete floor. Their hope in the future is to run a larger evaporator during the busy part of the season with the smaller one to supplement it or to use when sap production is lower.

The RO system is set up to have up to 15 units with about a dozen of them currently in use. Gene explained that they are able to remove up to 90% of the water from the syrup through this process. The concentrated sap goes to a storage tank before going to the evaporator and the pure water goes to tanks where it is used in cleaning.

Jon explains that they purchased a chiller from an area dairy farm to quickly reduce the temperature of the concentrated sap to about 28 degrees. Because of the concentration of sugar, syrup freezes at a lower temperature than water does. Typically sap that has got through the RO process only has a short shelf life before it must be cooked in the evaporator and packaged in barrels. Keeping the sap chilled in the tank lengthens the time for sap to be processed by days allowing them to be more efficient at times when the sap is not flowing as much.

Cleanliness is an important part of the production of any food product. Producing maple syrup is no different. In planning for the system they went with all stainless steel piping from Bob’s Dairy Supply of Dorchester and the plumbing was done by Zenner Plumbing and Heating of Medford and the electrical work done by McMillan Electric in Medford. There was a heavy emphasis on utilizing local businesses and craftsmen in building the new sugar shack from the delivery of more than 100 loads of fill material from Peterson and Sons for the base of the shack to fuel oil purchased through the Medford Cooperative and building materials purchased from Klingbeil Lumber.

Details such as the hard surfaced wallboard material allow for it to be kept clean easily and the addition of sturdy locally fabricated heavy-duty steps accessing the storage tanks and large garage doors make access easy for any future repairs or maintenance work. The attention to detail includes having the pump to offload sap from transport vehicles located indoors and accessed through a port in the wall. Being kept indoors helps improve the operation and efficiency of the pump. Chris notes that with a Y-connector they are able to offload two tankers of sap at once.

Outside the sugar shack and under their own roofed section are two massive open-topped storage tanks where the sap is pumped before being processed. The Knolls estimated they have about 15,000 trees tapped both in the forest surrounding the sugar shack and in other nearby areas where they own or lease land and through the season will run four vehicles from the collecting points to unload into the tanks.

From collecting sap for the past 10 years, the Knolls know the work involved in getting the trees tapped and the lines ready. Tapping trees is always a race as the weather starts to turn. On Saturday, Jon noted they had a crew of 19 tapping trees. Like many larger scale productions, they utilize a vacuum system that has lines strung from the trees to central collection points. While the suction helps in production, gravity plays a major role in getting the sap from the smaller feeder lines into the larger collectors.

Looking to the future Gene, who in his spare time enjoys showing off his restored tractors and taking people for rides on wagons modified to carry passengers, looks forward to when they can have classrooms of children at the sugar shack to learn about how syrup is made. Jon said he could see groups holding events at Sugar Moon Hills with its trails and space in the shack.

While the majority of the syrup will be sold on the wholesale market to be blended and used as ingredients, Sugar Moon Hills also offers local retail sales of the syrup and related items including hats and sweatshirts.

Winchell Construction did the framing with Doyle’s doing the interior finish and WFC poured the concrete for the new sugar shack located on Sunset Drive.

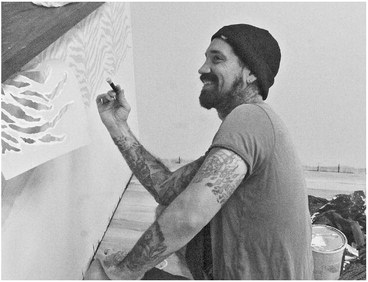

Sugar Moon Hills is a family operation with Gene Knoll (center) working with his sons Chris and Jonathon. Their spouses and children also pitch. The family has also been assisted in the past five years by Clay Bowe who was a student in the ag program.BRIAN WILSON/THE STAR NEWS