From field to fiber at Red Door Family Farm

People gathered at Red Door Family Farm in Athens on Saturday and learned how to harvest flax from the field and turn it into fibers to make linen fabric for clothing The activity was part of a flax harvest celebration held by the Marathon County Chapter of Wisconsin Farmers Union.

Stacey Botsford, co-owner of Red Door Family Farm with her husband, Tenzin, gave attendees a farm tour to show off the organic vegetables they grow on their 36acre farm, located northwest of Athens in the town of Bern. They rotate their crops each year, planting on 12 acres at a time.

Stacey told attendees they have six hoop houses where vegetables are grown. She said hoop houses are different than greenhouses because they are stuck into the ground and are not heated.

Alexandra Spaulding works as the field and market manager at Red Door Family Farm. She grows flax in a field on the farm so she can process it and spin it into linen. Spaulding gave the flax presentation at the farm on Saturday, along with Leslie Schroeder from Dane County, who founded Midwest Linen Revival.

Spaulding told attendees that she planted flax in April one day before there was a large rain storm.

“The rain pounded the seeds into the soil and then washed more soil of top of them, which put the seeds too far down into the ground, and when the seeds germinated, they struggled to get through the soil,” she said. “Planting depth is important.”

Spaulding also had trouble with deer nibbling on the flax plant leaves this summer, which is a new problem on the farm, but thankfully the plants recovered and are now flourishing. Flax requires little water during its 100-day growth cycle, as it thrives on morning dew and light rains.

Attendees enjoyed looking at the row of flax plants, which have a tall, slender stem with blue flowers. The fibers used to make linen are found in the inner part of the plant’s stem.

To extract the fibers, Schroeder said the flax stems of the plant are harvested and bundled into swathes. The flax then undergoes the process of retting, where the plant stems are exposed to moisture and bacteria to free the fibers from the rest of the stalk.

Schroeder told attendees there are two retting options: dew retting where flax stalks are spread in a field and exposed to dew and sunlight, or water retting where flax is submerged in water. After retting, the flax is spread out to dry to prevent mold and mildew from forming.

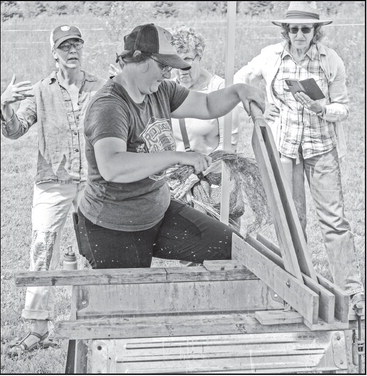

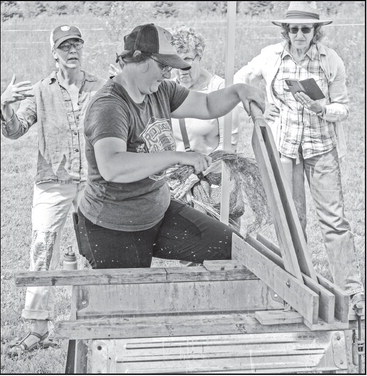

Spaulding conducted a demonstration for attendees using a wooden brake that her father made for her to “brake” the dried flax to separate the fibers from the woody core. She then hit the fiber with a wooden paddle to remove remaining stem material. Spaulding then combed the fiber through sharp tines in a wooden board to separate shorter fibers (tow) from the longer desirable fibers (line).

Schroeder said linen made from the fibers of the flax plant are one of the oldest textiles, having been used for thousands of years. She said linen is highly valued for its exceptional coolness and freshness in hot weather, as well as its durability.

“We can’t talk about clothing without talking about the massive problems in the current textile industry — its energy and resource consumption from start to finish,” Schroeder said. “ We’re wearing synthetic garments that shed micro plastics into our water. Flax gives us a chance to do better.”