A fixture on the dairy scene

By Mandee Ellis

Lynn Dairy is a large operation. It was purchased by Walter Schwantes in 1949, and the family is working on integrating their fourth generation into the enterprise. Lynn Dairy brings in 1.7 million pounds of milk a day and contracts with 320 farms locally.

“The cows work every day,” said quality assurance manager Kaylee Steponik. So Lynn Dairy does too.

Most of the farms that ship to Lynn have done so for generations. Field representative Karla Peterson believes that farmers partner with Lynn because they know that each farm matters. Whether it be a farm with 1,000 cows or an Amish operation that ships in milk cans, they all make an impact at Lynn.

“They feel like they don’t matter,” Peterson said of small dairy operations. “It doesn’t matter if you ship 200 pounds or 2,000 pounds, you matter.”

Lynn spends time cultivating relationships with their farmers, noting that changes in technology make a difference in their communications, with texting and emailing helping to keep things more convenient for everyone.

“That’s our bread and butter,” said Peterson, stating that their average farm milks about 75 cows. They’re ready to come out and help the farmers when needed, as it’s important to Lynn Dairy that each farm feels supported. It starts from the ground up with the milk haulers, who have all been with Lynn for a significant amount of time. They know their routes and the people responsible for getting milk in the silos inside and out.

Efficiencies in other areas have also helped streamline the entire process. Steponik and Peterson note that they’re bringing in more milk than ever, which means more cheese. They credit farmers for utilizing genetics in combination with higher quality feed to help their cows have better production, stating that some Holsteins are now able to produce richer milk like that of a Jersey, higher in butterfat and protein, while still putting out the pounds.

Lynn has increased their own production in response. Steponik said they were making 30 vats a day when she started six years ago, and today, Lynn Dairy is pumping out 42 vats or more on a daily basis. They’ve brought on more trucks and more employees and have installed an optimized, more automated airactivated system to handle what their farmers are churning out.

Production supervisor Andy Follen remembers doing a good chunk of the work manually. Instead, there now stands a fourstory mass of gleaming steel connected by belts that drops cheese from one level to the next, one of the only designs of its kind.

“It’s definitely different,” Follen said. Peterson said of their production, “It’s the best that the owners have ever seen.”

And what do they do with that milk? They transform it, and then they sell it.

Lynn Dairy produces 200,000 pounds of cheese per day. There isn’t much that they

See LYNN DAIRY/ page 3

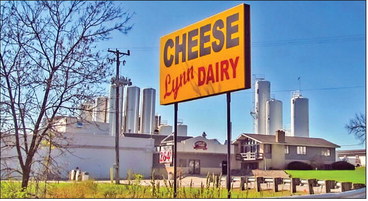

COME INSIDE AND SEE WHAT’S AVAILABLE - Lynn Dairy’s retail store is attached to their plant in Granton. In the shop you’ll find flavorful cheeses like cheddar, mozzarella and, of course, cheese curds in a variety of profiles made in part thanks to local farmers.

SUBMITTED PHOTO Lynn Dairy

Continued from page 2

won’t do with it, as they make cheddar, Colby, Monterey jack, pepper jack, mozzarella, farmers cheese and cheese curds. Most of this is sold in their retail store, but they’ll also ship it globally as long as they can do it safely and responsibly.

Their retail store, located at the plant in Granton, boasts fun and delicious options for everyone. There you can try chunks and hunks, sold as snack packs of cubed cheese and beef sticks, or their parmesan pizza. And, of course, they have a steady supply of cheese curds in a variety of different flavors courtesy of Lynn Dairy’s chief flavor officer who simply goes by the name, Killer. Steponik recommends the killer pepper cheddar, christened so for its namesake.

“I like to joke that we put a lot of love in our cheese,” she said of their curds which recently took second place in a nationwide competition.

They state that the retail store is more popular than ever with visitors coming from all over, most of them equipped with coolers and ice to be sure their treasures make it home, wherever that may be.

“We’ll have people come out from Canada, three hours, they make a trip here just for us,” Steponik said.

“Hunting season is insane,” Peterson said. “It’s rural Wisconsin.”

They stock precut cheese trays for the convenient get-together snack, and make cheese boxes for Christmas. Whatever the occasion, the perfect savory treat is available at Lynn.

They also make whey protein concentrate,

See LYNN DAIRY/ page 12

THE TEAM - Production supervisor Andy Follen, left, field representative Karla Peterson and quality assurance manager Kaylee Steponik work together, from milk collection to finished product, to ensure that each batch is of the highest quality.

STAFF PHOTO/MANDEE ELLIS Lynn Dairy

Continued from page 3

deproteinized whey and lactose with Lynn Proteins, a sibling venture to Lynn Dairy that was established in 1971.

Lactose is used to bake, make candy and even craft beer. They try to use as much byproducts as they can and find that their farmers and customers appreciate that sustainability.

With all this growth it would be easy for Lynn Dairy to lose sight of its employees, especially with about 160 people on the payroll, but that just hasn’t been the case. Several of their team members have been with the company for 20 or 30 years, and Peterson states that each one of them takes pride in what they do.

“It’s 100% passion, people honestly just care,” Steponik said.

They report that working at Lynn Dairy and Lynn Proteins feels like working for family, with Peterson stating that the management and CEO are present and always willing to lend a hand.

“Bill walks through the plant every day. You have a face with that signature on your check,” she said of president Bill Schwantes. When original purchaser Walter Schwantes passed away, his son, William W. Schwantes, took the reins before retiring in 1985 and leaving Bill in charge.

“We can all say we’re family ourselves,” Steponik said.

Lynn Dairy has stood the test of time, not only in their automation but in their retail market. They do this by going with the flow, taking whatever their farmers have to throw at them by way of production and making it work. It’s a team effort, and it goes to show that the dairy industry, just like the team at Lynn Dairy, really is a community.

“I don’t think there’s any way we’re ever going to go away from that,” Peterson said.