ticularly severe labor shortage. One ….

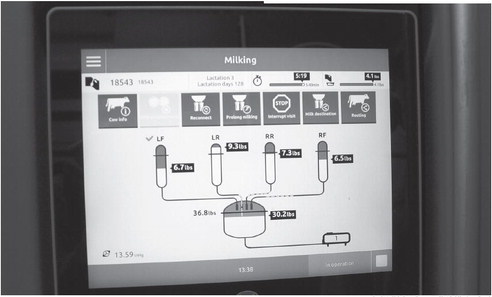

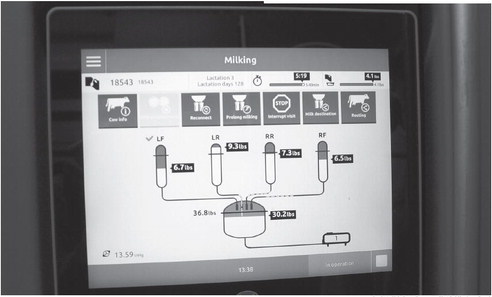

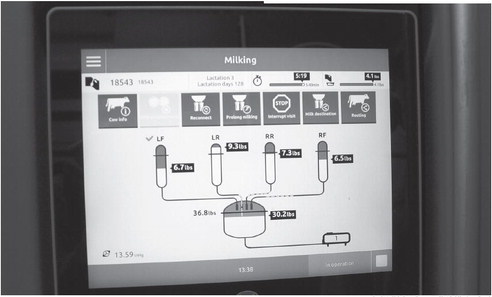

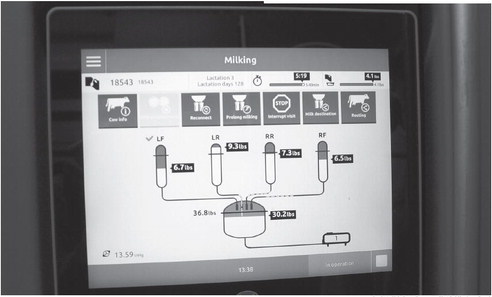

ticularly severe labor shortage. One potential solution is to replace labor with automated robot milkers. Another problem on the horizon is a lack of replacements for farmers who are ...

ticularly severe labor shortage. One potential solution is to replace labor with automated robot milkers. Another problem on the horizon is a lack of replacements for farmers who are ...