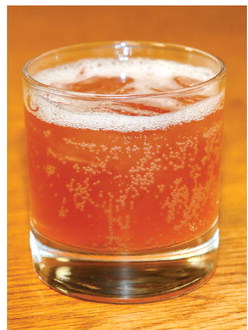

It’s all about living the sweet life

A visit to family-run Wellner's Sugar Shack

Have you ever had pancakes or waffles, drizzled with sticky, sweet, maple syrup and wondered how it was made? More goes into it than you can imagine and producing maple syrup is not for the faint of h...